Breakthroughs in EV Battery Recycling and Sustainability

Recent innovations in EV battery recycling show immense promise for enhancing sustainability. Researchers have developed advanced hydrometallurgical methods to recover valuable metals such as lithium, cobalt, and nickel. These methods enable efficient extraction while reducing environmental damage.

Several companies have deployed automated recycling systems that streamline the disassembly process. For instance, Redwood Materials and Li-Cycle use robotics to dismantle battery packs with precision. This not only improves safety but also boosts the recovery rate of critical materials.

Sustainable material sourcing has also seen significant advancements. Companies like Tesla and BMW now prioritize eco-friendly mining practices and ethical sourcing. By collaborating with suppliers ensuring human rights and environmental standards, these automakers work to make their supply chains more sustainable.

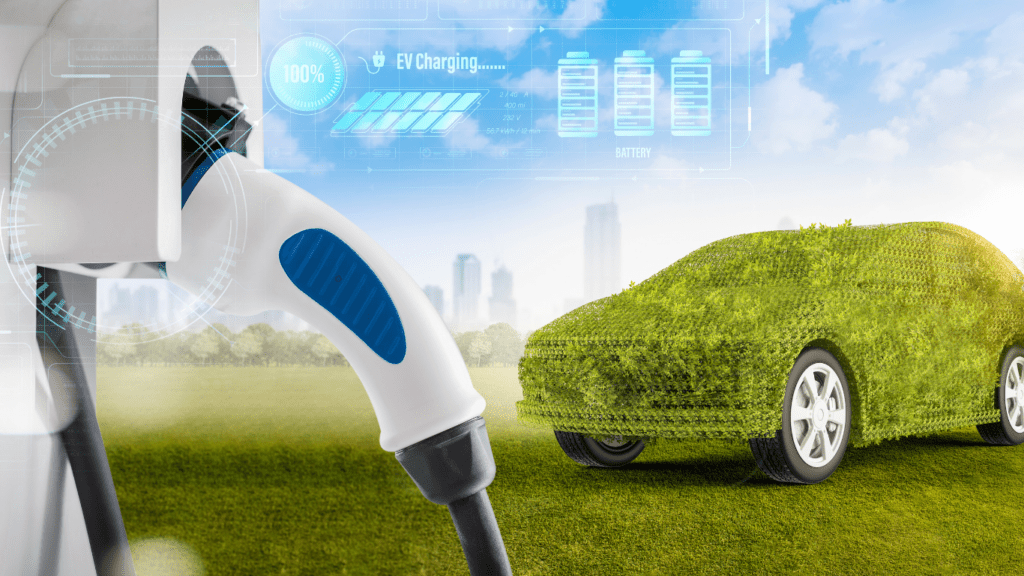

Battery second-life applications present an additional breakthrough. Used EV batteries can serve as energy storage solutions for renewable energy grids. Projects led by Nissan and Renault repurpose end-of-life batteries, thus prolonging their utility and reducing waste.

Innovative chemical processes have emerged for reconditioning old batteries. Companies like RecycLiCo have developed processes that refresh battery materials, restoring their capacity and extending their lifespan. This reduces the need for raw material extraction and lowers the overall environmental footprint.

These breakthroughs indicate a clear shift towards a circular economy for EV batteries. By focusing on recycling, second-life applications, and sustainable sourcing, the industry actively addresses environmental challenges and promotes long-term sustainability.

The Importance of EV Battery Recycling

Recycling EV batteries plays a crucial role in reducing environmental harm and fostering economic growth. It’s a pivotal component of sustainable practices in the rapidly evolving EV industry.

Environmental Impact

- Recycling EV batteries dramatically lowers the environmental footprint.

- Instead of relying on mining raw materials (e.g., lithium, cobalt, nickel), recycling recovers these valuable metals from used batteries.

- This reduces habitat destruction, water usage, and greenhouse gas emissions associated with traditional mining.

- Companies like Redwood Materials focus on efficient recycling methods, significantly lowering the environmental impact while maximizing material reuse.

- Additionally, proper recycling mitigates the risk of hazardous waste, ensuring toxic substances don’t contaminate soil and water sources.

Economic Benefits

The economic advantages of recycling EV batteries are substantial. Extracting precious metals through recycling is more cost-effective compared to mining. This reduction in costs positively impacts the market by lowering battery production expenses, which can lead to more affordable EVs for consumers. Companies like Li-Cycle and RecycLiCo have demonstrated that investing in recycling infrastructure also creates jobs, spurring economic growth in local communities. By extending battery life through reconditioning, the financial burden of frequent replacements diminishes. This shift towards a circular economy reduces dependency on volatile raw material markets and promotes financial stability in the EV sector.

Recent Innovations in Battery Recycling Technologies

Recent innovations in EV battery recycling have propelled the industry towards higher efficiency and sustainability. Advanced methods and cutting-edge chemical processes are redefining the approach to recycling EV batteries.

Advanced Separation Techniques

Advanced separation techniques have revolutionized the way valuable materials are extracted from used batteries. Companies like Redwood Materials and Li-Cycle use automated systems to disassemble batteries, optimizing safety and material recovery rates. These automated methods ensure precise separation of:

- lithium

- cobalt

- nickel

reducing waste and minimizing environmental impact. Hydrometallurgical processes further enhance this separation by using aqueous chemistry for metal recovery, thereby replacing energy-intensive smelting techniques.

Chemical Recycling Methods

Chemical recycling methods are at the forefront of extending battery life and reducing resource extraction. RecycLiCo has pioneered processes to recondition old batteries by restoring the chemical integrity of battery materials. This method not only extends the lifespan of the batteries but also reduces the need for new raw material extraction. By chemically treating used batteries, valuable metals are recovered more efficiently, lowering the overall environmental footprint associated with traditional mining operations.

Sustainability Practices in the EV Industry

The EV industry is embracing sustainability practices to minimize environmental impact and enhance resource efficiency. These efforts contribute to a more eco-friendly and economically viable future for electric mobility.

Circular Economy Initiatives

Several companies implement circular economy initiatives to promote sustainability. For instance, automakers like Nissan and Renault repurpose used EV batteries for energy storage, integrating them into renewable energy grids. These second-life applications extend the utility of batteries, reducing waste and conserving resources. Additionally, Redwoods Materials emphasizes the importance of recovering valuable materials from spent batteries through automated recycling systems, ensuring these resources re-enter the supply chain.

Partnerships and Collaborations

Collaborations play a critical role in advancing sustainability. Tesla partners with suppliers adhering to ethical sourcing and eco-friendly mining practices, ensuring the integrity of its supply chain. Furthermore, BMW collaborates with recycling firms to develop efficient material recovery techniques, reducing the dependency on raw material extraction. Through these partnerships, companies like Li-Cycle and RecycLiCo innovate in battery recycling and reconditioning, creating a sustainable ecosystem that supports both environmental and economic objectives.

Challenges and Opportunities

Rapid developments in EV battery recycling present both challenges and opportunities for the industry. Addressing these elements ensures sustainable advancements aligning with environmental and economic objectives.

Technical Challenges

Efficient recycling methods must overcome several technical hurdles. Extraction processes for valuable metals like lithium and cobalt require precision to prevent material loss and contamination. For instance, while hydrometallurgical methods of metal recovery show promise, they must optimize to minimize harmful byproducts. Battery disassembly automation faces complications due to varying battery designs. Companies like Li-Cycle must innovate to accommodate diverse battery architectures without compromising safety. Furthermore, precise separation techniques need refinement to enhance the purity of recovered materials, ensuring they meet high manufacturing standards.

Market Opportunities

Sustainable practices in battery management open up significant market opportunities. Enhanced recycling methods lower production costs by reclaiming valuable materials, contributing to more affordable EVs.

Companies investing in cutting-edge recycling technologies, such as Redwood Materials, gain a competitive edge in the market. Additionally, second-life battery applications create new revenue streams. Repurposing used batteries for renewable energy storage, as executed by Nissan and Renault, offers solutions to energy distribution challenges.

Chemical reconditioning processes restore old batteries, extending their lifespan and providing cost-effective alternatives to immediate replacement. This investment in recycling infrastructure generates jobs and fosters local economic development, driving the adoption of EVs on a larger scale.

Future Prospects

Exploring future prospects in EV battery recycling reveals exciting research trends and policy advancements aimed at bolstering sustainability.

Upcoming Research and Developments

Innovations in recycling technology will revolutionize EV battery sustainability. Researchers are advancing solid-state battery designs to offer higher energy density and lower environmental impact. For example, companies like QuantumScape and Solid Power are pioneering these efforts with promising results.

Additionally, AI and machine learning are being integrated to optimize recycling processes, as seen in projects by IBM and MIT. Enhanced AI algorithms promise to improve material recovery rates and efficiency. Scientists are also working on developing less toxic and more recyclable battery chemistries, such as sodium-ion and lithium-sulfur batteries, which can potentially replace traditional lithium-ion technology.

Policy and Regulations

Policy and regulations will play a critical role in the evolution of EV battery recycling. Governments worldwide are enacting laws to enforce responsible recycling practices. The European Union’s Battery Directive mandates recycling targets and promotes sustainable practices in battery disposal.

Similarly, the US is exploring policies to incentivize recycling, with the Department of Energy supporting initiatives like ReCell Center, dedicated to advanced battery recycling R&D. Regulatory frameworks encourage manufacturers to design batteries with recycling in mind, making it easier to recover valuable materials and reduce environmental impact. These policies will drive innovation and ensure widespread adoption of sustainable practices across the industry.