Overview of Next-Generation EV Motors

Next-generation EV motors represent a significant leap in technology compared to traditional electric motors. These advancements focus on increasing efficiency, power density, and overall performance. Manufacturers are using new materials like rare-earth magnets and silicon carbide (SiC) components to improve motor capabilities.

- Higher Efficiency

New EV motors achieve higher efficiency by reducing energy loss. They use advanced cooling systems, minimizing heat generation and preserving battery life. Increased efficiency extends vehicle range, making EVs more practical for longer trips. - Improved Power Density

Enhanced power density means more power from a smaller motor. This improvement allows for lighter vehicles, better performance, and increased interior space. By using lightweight materials and innovative designs, manufacturers can fit more powerful motors without increasing the vehicle’s weight. - Advanced Cooling Systems

Improved cooling systems prevent overheating and enhance motor longevity. Liquid cooling is common in cutting-edge models, providing consistent temperature management even under high loads. Effective cooling ensures optimal performance and reliability. - Reduced Rare-Earth Dependency

Some next-gen motors minimize the use of rare-earth materials, which are expensive and environmentally damaging to mine. By incorporating technologies like induction or synchronous reluctance motors, manufacturers can achieve similar performance with more sustainable materials. - Smart Motor Controls

Advanced motor control systems enhance efficiency and responsiveness. These systems use algorithms and sensors for real-time adjustments, optimizing performance based on driving conditions. Smart controls also contribute to energy conservation and better driving experiences. - Integration with EV Ecosystem

Next-gen motors integrate seamlessly with the entire EV ecosystem, including batteries, power electronics, and charging infrastructure. This integration allows for more efficient energy use, faster charging times, and improved vehicle-to-grid interactions. - Future Prospects

Next-generation motors are set to bring further advancements in efficiency, performance, and sustainability. Continuous research in materials science and electronic engineering promises even more innovative solutions for future EVs.

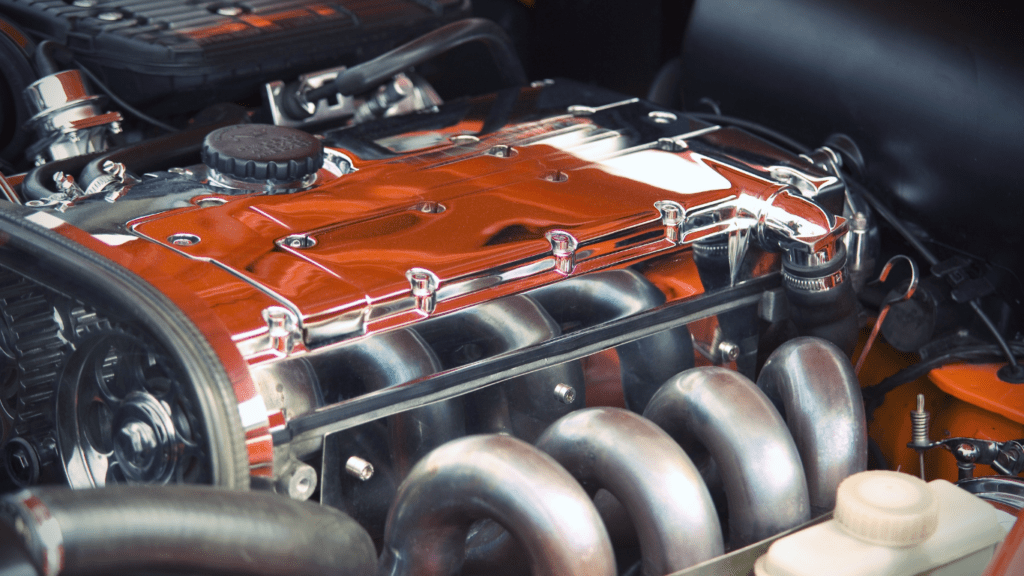

Key Technological Advancements

Next-generation EV motors are pushing boundaries with several key technological advancements revolutionizing the industry.

Enhanced Efficiency

New materials and designs are boosting the efficiency of EV motors. Incorporating rare-earth magnets and silicon carbide (SiC) components significantly reduces energy loss. Advanced cooling systems minimize heat generation, ensuring longer battery life and making EVs more practical for extended use. Smart motor control systems optimize performance in real-time, adapting to different driving conditions to ensure optimal energy use.

Increased Power Density

Next-gen EV motors deliver more power from smaller units, thanks to the use of innovative materials. This increased power density results in lighter vehicles, leading to better performance and more interior space. Technologies like induction or synchronous reluctance motors are helping reduce reliance on rare-earth materials while still delivering high performance. Smaller motors also contribute to better vehicle dynamics, improving overall driving experience.

Thermal Management Improvements

Advanced thermal management systems are crucial for extending motor longevity. Liquid cooling systems efficiently manage heat, preventing overheating and enhancing motor life. Effective thermal management ensures consistent performance even under high stress or extended use. As a result, EVs can handle longer trips with better reliability. These improvements not only enhance efficiency but also contribute to the overall sustainability of the vehicle.

New Materials and Design Approaches

Next-generation EV motors are benefiting from innovative materials and design methods that boost performance and sustainability. Advanced composites and new magnetic materials are leading this transformation.

Lightweight Composites

Manufacturers are using lightweight composites to reduce vehicle weight while maintaining structural integrity. Carbon fiber and reinforced polymers, for example, are popular choices. These materials significantly cut down the overall mass of the vehicle, which improves both efficiency and range. Lighter vehicles require less energy to move, directly enhancing battery performance and extending driving distances.

Advanced Magnetic Materials

Advanced magnetic materials, especially rare-earth magnets like neodymium-iron-boron (NdFeB), are at the forefront of modern EV motor development. These magnets generate strong magnetic fields that allow for smaller, more efficient motors. By optimizing magnetic flux, manufacturers achieve higher torque and power density. Additionally, research into alternative magnetic materials, such as iron-nitride, aims to reduce reliance on rare-earth elements, making EV production more sustainable.

Impact on Performance and Range

Next-generation EV motors bring substantial improvements in both performance and range, enhancing the overall driving experience.

Acceleration and Top Speed

New advancements in EV motors boost both acceleration and top speeds significantly. Next-gen motors provide higher torque, which results in rapid acceleration and a more thrilling driving experience. For example, a Tesla Model S Plaid can accelerate from 0 to 60 mph in under 2 seconds, showcasing the motor’s capabilities. These motors also support higher sustained speeds due to better thermal management systems, such as liquid cooling, preventing overheating and maintaining performance even during extended high-speed drives.

Enhanced Battery Efficiency

Innovative motor designs contribute to enhanced battery efficiency by minimizing energy loss. Motors equipped with advanced controllers can optimize energy use based on real-time conditions, extending the driving range. For instance, the integration of silicon carbide (SiC) components significantly reduces energy waste. Additionally, more efficient motors reduce dependency on large batteries, making EVs lighter and further boosting range. Improved thermal management also means batteries don’t overheat, which extends their lifespan and reliability.

Leading Manufacturers and Innovations

Next-gen EV motors are shaping the future of transportation. Several key manufacturers are driving these advancements with notable innovations.

Major Players in the Market

Tesla leads the industry with its advanced electric motors, renowned for their efficiency and power. The Tesla Model S Plaid showcases this with a 0-60 mph time under 2 seconds. Rivian is another significant player, focusing on electric trucks and SUVs with impressive performance. Their R1T and R1S models highlight cutting-edge motor technology. Lucid Motors stands out with its Air model, boasting up to 1,111 horsepower and a 500-mile range, leveraging advanced aerodynamics and motor design.

Notable Recent Innovations

Tesla’s use of silicon carbide in its inverters significantly enhances efficiency and range. Rivian’s quad-motor system allows precise torque control, optimizing off-road and on-road performance. BMW has introduced innovative cooling systems with its fifth-generation eDrive technology, ensuring consistent performance. Additionally, General Motors’ Ultium platform focuses on modularity, allowing various battery and motor configurations across different vehicle models for optimized performance.

Future Prospects and Trends

Advancements in EV motors continue to unfold rapidly. Next-gen motors promise exciting innovations in both technology and industry practices.

Emerging Technologies

Emerging technologies in the EV motor sector are pushing boundaries. Solid-state batteries, for instance, increase energy density and reduce charging times, enhancing overall efficiency (source: Nature Energy). Gallium nitride (GaN) semiconductors replace silicon, providing benefits like lower energy loss and higher efficiency. Induction and synchronous reluctance motors, which use minimal rare-earth materials, offer comparable performance with more sustainable options. Similarly, wireless charging technology improves convenience and usability, eliminating the need for plugged-in charging.

Industry Predictions

The EV motor industry is set to see several key trends. Market analysts project the global EV market to reach $802.81 billion by 2027, driven largely by innovations in EV motors and battery technologies (source: Allied Market Research). Companies aim to phase out fossil fuel vehicles by 2035, spurred by stringent government regulations and consumer demand for sustainable alternatives. Autonomous EV technologies, coupled with advanced motors, promise fully self-driving vehicles within the next decade. Higher investments in R&D are expected to yield more breakthroughs, from ultra-fast charging solutions to AI-driven motor controls, solidifying the role of EVs in mainstream transportation.