Understanding Brake Components

Proper brake maintenance requires a solid grasp of key components. Each part plays a crucial role in ensuring the brake system’s effective operation.

- Brake Pads

Brake pads apply friction to the rotors to slow down or stop the vehicle. Typically made of materials like organic, semi-metallic, or ceramic, they wear down over time and need regular inspection.

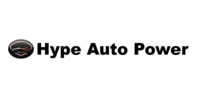

- Rotors

Rotors, also known as brake discs, are the surfaces against which the brake pads press. These metal discs convert kinetic energy into thermal energy. Warped or damaged rotors can cause vibrations and reduced braking efficiency.

- Brake Calipers

Brake calipers house the brake pads and use hydraulic pressure to clamp them onto the rotors. A malfunctioning caliper can lead to uneven pad wear or a stuck brake, affecting the vehicle’s stopping power.

- Brake Lines

Brake lines carry hydraulic fluid from the master cylinder to the calipers. They must remain free from leaks, cracks, or air to maintain consistent braking pressure. Regular checks help ensure the integrity of these lines.

- Master Cylinder

The master cylinder generates hydraulic pressure to activate the brake calipers. It’s essential for converting pedal force into braking power. Any issues with the master cylinder can compromise the entire system’s functionality.

- Brake Fluid

Brake fluid transfers force from the brake pedal to the calipers. This fluid is prone to absorbing moisture, which can reduce performance. Regular fluid checks and replacements keep the system efficient.

Understanding these vital components helps maintain your brakes for optimal performance. Each part’s condition influences overall braking effectiveness and vehicle safety.

Signs Your Brakes Need Maintenance

Recognizing early signs of brake issues can prevent costly repairs and ensure your safety. Let’s look at some key indicators that your brakes need attention.

Squeaking or Grinding Noises

Unusual noises like squeaking or grinding often signal worn brake pads. Brake pads have built-in indicators that emit a high-pitched sound when they’re too thin. Ignoring these noises could damage the rotors. If you hear grinding, the brake pads might be entirely worn down, causing metal-on-metal contact. This situation demands immediate attention to avoid further damage to the braking system.

Vibrations or Pulsations

Feeling vibrations or pulsations in the brake pedal or steering wheel typically points to rotor issues. Warped rotors occur due to excessive heat or uneven wear, disrupting the smooth contact between pads and rotors. This uneven contact generates pulsations felt through the pedal. If vibrations persist, I recommend having a professional measure rotor thickness and smoothness to determine the need for resurfacing or replacement.

Soft or Spongy Brake Pedal

A soft or spongy brake pedal indicates possible air in the brake lines or issues with the brake fluid. Air in the hydraulic system reduces braking efficiency, making the pedal feel less responsive. Additionally, old or contaminated brake fluid can fail to sustain the necessary hydraulic pressure. Check the brake fluid level and quality and bleed the brake lines to remove air if a soft pedal occurs.

Essential Tools and Supplies

Maintaining your brakes requires specific tools and supplies to ensure tasks are performed correctly and efficiently. Using these tools helps in maintaining optimal braking performance, preventing issues from escalating.

Brake Fluid

It’s essential to use the correct type of brake fluid recommended by your vehicle manufacturer. Always check fluid levels regularly to avoid performance problems.

Brake Cleaner

This spray cleans brake components without leaving residue. It’s vital during inspection or replacement to ensure no contaminants affect brake efficacy.

Jack and Jack Stands

A hydraulic jack lifts the vehicle, while jack stands securely hold it up. These tools are necessary for any under-vehicle maintenance, ensuring safety throughout the process.

Lug Wrench

A lug wrench helps remove the wheel nuts, providing access to the brake components. It’s an essential part of the brake maintenance toolkit.

C-Clamp or Brake Caliper Tool

Use a C-clamp or a special brake caliper tool to compress the caliper piston when replacing brake pads. This ensures the new pads fit properly.

Torque Wrench

A torque wrench ensures bolts and nuts, especially those securing calipers and wheels, are tightened to the specified torque. Proper torque is crucial for safety.

Brake Pad Spreader

A brake pad spreader separates the brake pads from the rotor, making it easier to remove and install new pads. It’s particularly useful for DIY brake maintenance.

Safety Glasses and Gloves

Safety gear, like glasses and gloves, protects against debris and brake fluid contact. Always wear them to maintain safe working conditions.

Wheel Chocks

Wheel chocks prevent the vehicle from moving while it’s lifted, providing additional safety. Use them on the opposite wheels to ensure stability during maintenance.

Having these tools and supplies ensures you’re prepared for any brake maintenance task, helping keep braking systems in optimal condition.

Step-by-Step Brake Maintenance Guide

In this section, I’ll provide detailed instructions to help maintain your vehicle’s brakes. Follow these steps to ensure optimal performance and safety.

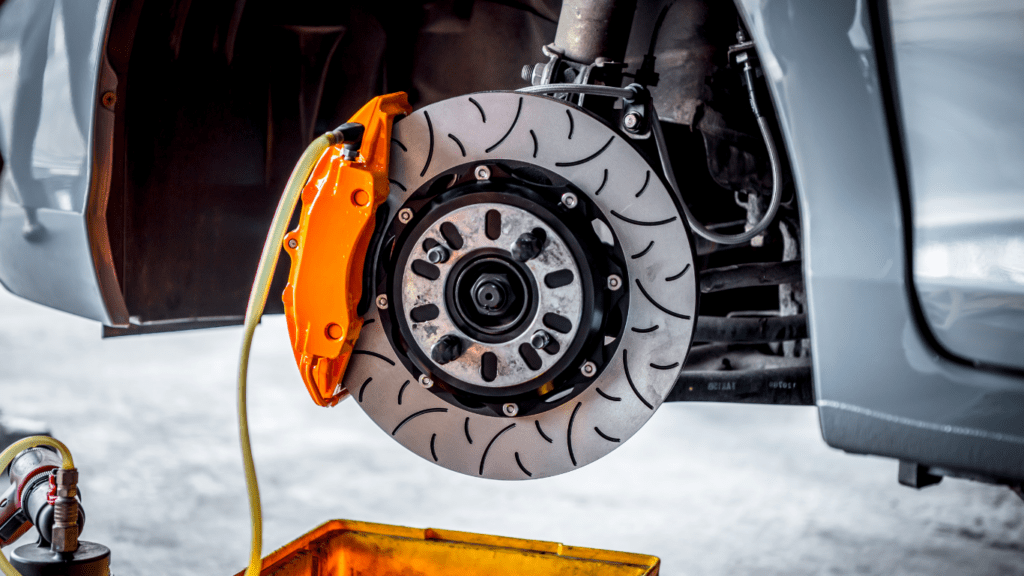

Inspecting Brake Pads and Rotors

Regularly check the condition of your brake pads and rotors. To do this:

- Lift the Vehicle: Use a hydraulic jack to raise the vehicle and secure it with jack stands.

- Remove the Wheels: Use a lug wrench to loosen and remove the wheel nuts, then take off the wheels.

- Inspect Brake Pads: Examine the brake pads for wear. If the pad thickness is below 3-4mm, replace them. Worn pads often have uneven surfaces or visible metal.

- Check Rotors: Look for signs of damage or wear on the rotors. Warped or grooved rotors might cause vibrations when braking and should be replaced or resurfaced if necessary.

Checking Brake Fluid Levels

Maintaining proper brake fluid levels is critical since it acts as the hydraulic medium.

- Locate the Master Cylinder: Typically found near the brake booster in the engine bay.

- Check Fluid Level: Ensure the fluid is between the “MIN” and “MAX” marks on the reservoir. Low levels might indicate a leak or worn brake pads.

- Inspect Fluid Condition: Brake fluid should be clear or light amber. Dark or contaminated fluid needs replacing to maintain braking efficiency.

Bleeding the Brakes

Bleeding brakes removes air from the brake lines, ensuring firm pedal feel and efficient braking.

- Prepare the Vehicle: Lift the vehicle and remove the wheels to access the calipers.

- Locate Bleeder Valves: Each brake caliper has a bleeder valve that needs to be accessed.

- Attach Tubing: Connect clear plastic tubing to the bleeder valve and place the other end in a container partially filled with brake fluid.

- Bleed the Brakes: Have a helper press the brake pedal while you open the bleeder valve. Close the valve before the pedal is released. Repeat until no air bubbles are visible in the tubing.

Lubricating Brake Components

Proper lubrication of moving parts prevents noise and ensures smooth operation.

- Apply Brake Lubricant: Use a high-temperature brake grease on caliper slides, pins, and the contact points of the pads and calipers.

- Avoid Rotor Surface: Ensure lubricant doesn’t touch the rotor or pad friction surfaces. Contamination can severely degrade braking performance.

- Reassemble Components: Once everything is properly lubricated, reassemble the brake components and wheels, ensuring all bolts are torqued to the manufacturer’s specifications.

Following these steps keeps your braking system in prime condition, enhancing safety and performance.

Tips for Extending Brake Life

Regularly checking brake fluid ensures the braking system functions correctly. Low or dirty brake fluid decreases efficiency, leading to potential brake failure. I recommend inspecting brake fluid levels monthly and replacing it every two years, as advised by automotive experts.

Avoiding aggressive driving can significantly extend brake life. Frequent hard braking generates excessive heat, contributing to faster wear of brake pads and rotors. By maintaining safe distances and anticipating stops, drivers can reduce the stress on their braking systems.

Properly maintaining the brake hardware helps prevent premature wear. Rust and corrosion can affect components like calipers and slide pins, reducing their effectiveness. I suggest cleaning and lubricating these parts during regular inspections to maintain optimal performance.

Using quality brake components is crucial for ensuring longevity. Cheaper parts often wear out faster, requiring more frequent replacements. Investing in high-quality pads and rotors can save money and enhance braking performance in the long run.

Regular tire maintenance impacts brake efficiency. Properly inflated and aligned tires ensure even pressure distribution, reducing uneven wear on brake components. I find checking tire pressure monthly and getting alignments annually improves overall braking performance.

Mindful driving improves brake longevity. When driving in traffic, I avoid stop-and-go patterns by coasting to slow down instead of relying heavily on the brakes. This minimizes wear and helps maintain a smoother braking system.

By implementing these tips, drivers can significantly extend the life of their brakes, ensuring safer and more efficient performance.

Common Brake Maintenance Mistakes to Avoid

Neglecting Regular Inspections

Ignoring regular brake inspections leads to undetected issues that can escalate. Brake pads, rotors, and fluid levels require consistent checks to ensure they’re within safe operating limits. Skipping these inspections increases the risk of sudden brake failure.

Using Incorrect Brake Parts

Incorrect brake parts, such as mismatched brake pads or rotors, compromise braking efficiency and safety. Always use manufacturer-recommended components. If unsure, consult your vehicle’s manual or a trusted mechanic. Using the wrong parts can lead to uneven wear and reduced performance.

Failing to Replace Brake Fluid

Over time, brake fluid absorbs moisture, reducing its effectiveness and potentially causing brake failure. Regularly replacing brake fluid is critical. Most manufacturers recommend doing this every 20,000 to 45,000 miles or as specified in your vehicle’s manual. Test the fluid using a brake fluid tester to ensure it remains within safe parameters.

Ignoring Unusual Noises

Unusual noises, such as squeaking or grinding, usually indicate worn-out brake pads or other issues. Ignoring these sounds can lead to severe damage. When you hear such noises, inspect the brake system immediately. Prompt attention avoids costly repairs and potential safety hazards.

Incorrect Brake Pad Installation

Incorrectly installing brake pads impacts braking performance and can cause damage. Ensure the pads are correctly aligned and securely mounted. Follow the instructions provided or seek professional help. Mistakes during installation result in uneven wear and reduced braking efficiency.

Overlooking Brake Caliper Maintenance

Brake calipers play a crucial role in the braking system. Failing to maintain them results in diminished stopping power. Regularly clean and lubricate calipers, checking for signs of wear or damage. Proper caliper maintenance ensures consistent performance and safety.

Conclusion

Maintaining your vehicle’s brakes is crucial for both safety and performance. By understanding the key components and recognizing signs of wear, you can prevent costly repairs and dangerous situations. Equipped with the right tools and following a detailed maintenance guide, you can keep your braking system in top condition.

Remember to adopt mindful driving habits and avoid common maintenance mistakes. Regular inspections and timely interventions will ensure your brakes remain reliable and effective. Taking these steps not only enhances safety but also extends the life of your braking system, giving you peace of mind on the road.